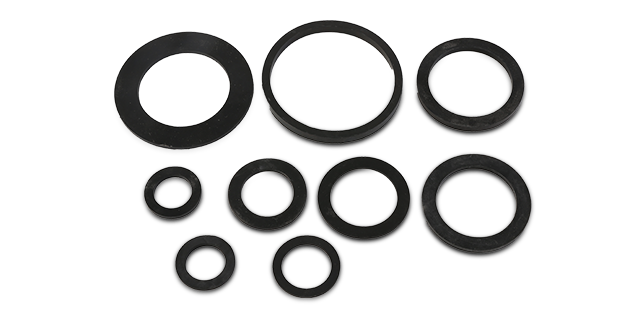

Bearing rubber sleeves are used for a variety of purposes in the mechanical and industrial fields. Their main purpose is to provide protection to bearings, which are important components of the machinery that allow parts to move and rotate smoothly.

One of the primary functions of bearing rubber sleeves is to prevent contamination of the bearing itself. Bearings are typically made of metal and can be damaged or corroded by exposure to dirt, dust, or moisture. Bearing rubber sleeves act as a barrier, preventing these contaminants from reaching the bearing and potentially causing damage. This helps to prolong the life of the bearing and prevent costly repairs or replacements.

Bearing rubber sleeves also provide a layer of cushioning between the bearing and other moving parts of the machinery. This helps to reduce the amount of friction and wear on the bearing, which can lead to a longer lifespan for the bearing and the machinery as a whole. The rubber material also helps to absorb shock and vibration, which can further protect the bearing and prevent damage.

In addition to providing protection and cushioning, bearing rubber sleeves can also help to reduce noise and vibration in the machinery. This is particularly important in applications where noise levels need to be kept to a minimum, such as in hospitals or other noise-sensitive environments.

Another important function of bearing rubber sleeves is to provide a seal between the bearing and its housing. This helps to prevent lubricant from leaking out of the bearing and potentially causing damage to other components of the machinery. The rubber material used in the sleeve also helps to resist the effects of heat and chemicals, ensuring that the seal remains effective over time.

Bearing rubber sleeves are generally made of fluorine rubber and silicone nitrile rubber. Choosing between fluorine rubber (FKM) and silicone nitrile rubber (NBR) for bearing rubber sleeves depends on a number of factors, including the specific requirements of the application, the temperature and chemical environment the sleeves will be exposed to, and the budget for the project.

Fluorine rubber is known for its excellent chemical resistance, particularly to fuels, oils, and chemicals. It is also resistant to high temperatures, with a maximum operating temperature of around 200°C (392°F). This makes it a good choice for applications where chemical resistance and high-temperature stability are important, such as in the aerospace and automotive industries. Fluorine rubber is also more expensive than other rubber materials, so it may not be the best choice for applications where cost is a primary concern.

Silicone nitrile rubber, on the other hand, is known for its excellent resistance to water, steam, and other low-molecular-weight polar fluids. It is also resistant to high temperatures, with a maximum operating temperature of around 150°C (302°F). This makes it a good choice for applications where water or steam resistance is important, such as in the food and beverage industry. Silicone nitrile rubber is generally less expensive than fluorine rubber, making it a more budget-friendly option.

When choosing between fluorine rubber and silicone nitrile rubber for bearing rubber sleeves, it is important to consider the specific requirements of the application, including the temperature and chemical environment the sleeves will be exposed to. It may also be necessary to consult with a rubber manufacturer to determine the best material for the specific application.

English

English-5.jpg?imageView2/2/format/jp2)

-5.jpg?imageView2/2/format/jp2)

-6.jpg?imageView2/2/format/jp2)

-8.jpg?imageView2/2/format/jp2)

-5.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)