How Are Rubber Guard Coils Used in Industrial Applications?

Rubber guard coils are commonly used in industrial applications to protect cables from damage caused by abrasion, chemicals, moisture, and other environmental factors. They can be used in a variety of settings, including manufacturing plants, construction sites, and transportation infrastructure.

In industrial applications, rubber guard coils are typically installed around cables that need to be protected, such as electrical wiring, data cables, or hydraulic hoses. The rubber material of the guard coil provides a barrier between the cable and any potential sources of damage, preventing abrasion or other types of wear and tear.

Rubber guard coils are also flexible, allowing them to conform to the shape of the cable they are protecting. This flexibility makes them useful in situations where the cable needs to be able to move or bend, such as in machinery or vehicles.

Rubber guard coils can also be used in industrial applications where cables are exposed to harsh outdoor environments, such as extreme temperatures, moisture, and UV radiation. In these settings, rubber guard coils can help to prolong the life of cables by preventing them from deteriorating or becoming brittle over time.

In addition to protecting cables from damage, rubber guard coils can also provide a layer of insulation to help prevent electrical shocks or other hazards. This is particularly important in industrial settings where workers are handling equipment that has live electrical components.

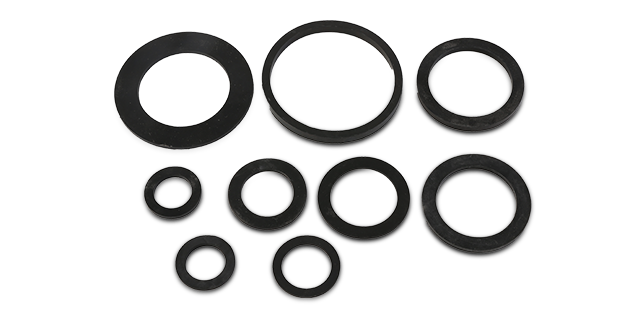

Rubber guard coils come in a variety of sizes and configurations to accommodate different types of cables and installation requirements. Some guard coils have a split design, allowing them to be easily installed over existing cables without the need for cable disconnection or cutting.

Rubber guard coils are a popular method for protecting cables in a variety of industrial applications, from construction sites to manufacturing plants. Installing rubber guard coils around cables is a relatively simple process that can be done in a few steps.

(1)Determine the length of the guard coil needed - Before you begin, measure the length of the cable you want to protect. This will help you determine the length of the rubber guard coil needed to fully cover the cable.

(2)Cut the guard coil to length - Once you have determined the length of the guard coil needed, use a pair of scissors or a sharp knife to cut the guard coil to the appropriate length.

(3)Open the guard coil - Most rubber guard coils have a split design that allows them to be easily opened and installed around the cable. To open the guard coil, simply locate the split in the coil and gently pry it apart.

(4)Slide the guard coil onto the cable - With the guard coil open, slide it onto the cable, making sure it is positioned correctly and covers the entire length of the cable.

(5)Close the guard coil - Once the guard coil is in place, use your fingers to gently press the split together until it snaps closed around the cable. Make sure the split is securely closed and the guard coil is snugly in place.

In addition, make sure the guard coil is the right size for the cable you want to protect. The guard coil should fit snugly around the cable without being too tight or too loose.

English

English

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)