How can rubber products be customized to fit specific applications?

Rubber products are used in a wide range of industries and applications, and their properties can be customized to fit specific requirements. Customization allows manufacturers to create rubber products that meet the exact needs of their customers, whether it's for strength, flexibility, temperature resistance, or other specific characteristics.

There are several ways that rubber products can be customized to fit specific applications:

(1)Material selection: The selection of the rubber material used in the product can be tailored to the specific application. Different types of rubber have varying properties, such as temperature resistance, chemical resistance, and electrical conductivity, so choosing the right material is critical.

(2)Hardness: The hardness of rubber products can be customized by varying the amount of filler used in the manufacturing process. More filler results in a harder product, while less filler produces a softer product.

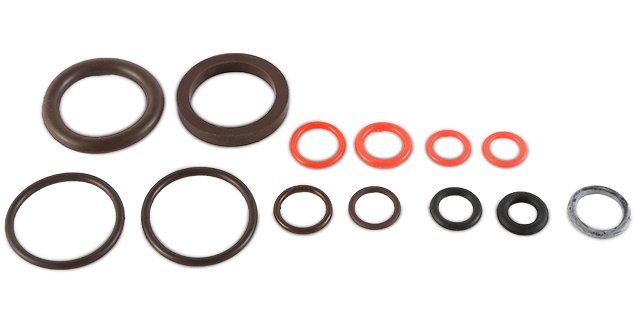

(3)Color: Rubber products can be customized with different colors to match branding or aesthetic requirements.

(4)Size and shape: Rubber products can be manufactured in a wide range of sizes and shapes to fit specific applications. Custom tooling can be created to produce unique shapes that are not readily available in the market.

(5)Thickness: The thickness of rubber products can be customized to fit specific applications. Thicker products offer greater durability and resistance to wear and tear, while thinner products are more flexible and easier to bend.

(6)Adhesive properties: Rubber products can be manufactured with specific adhesive properties, such as a pressure-sensitive adhesive, to allow for easy installation or bonding to other materials.

(7)Surface finish: The surface finish of rubber products can be customized to meet specific requirements, such as a smooth surface for easy cleaning or a textured surface for increased grip.

Customizing rubber products to fit specific applications is essential to ensure the optimal performance of the product. Taizhou Jiasheng has excellent and stable product quality. In this, rubber sealing strips of different cross-sections and materials can be customized according to customer requirements.

What factors should be considered when selecting a specific application rubber product?

(1)Material: The type of rubber material used in the product should be considered, as different materials have varying properties that may affect performance, such as temperature resistance, chemical resistance, and electrical conductivity.

(2)Hardness: The hardness of the rubber should be considered, as it can affect the product's durability, flexibility, and ability to withstand wear and tear.

(3)Temperature resistance: The temperature range that the rubber product will be exposed to should be considered, as some rubbers may degrade or lose flexibility at extreme temperatures.

(4)Chemical resistance: The chemical environment that the rubber product will be exposed to should be considered, as some chemicals can cause degradation or damage to certain rubbers.

(5)Pressure and weight-bearing capacity: The amount of pressure or weight that the rubber product will need to support should be considered, as it can affect the product's ability to maintain its shape and function over time.

(6)Environmental factors: The environmental conditions that the rubber product will be exposed to should be considered, such as exposure to UV light, ozone, or moisture, as these can affect the product's durability and longevity.

(7)Size and shape: The size and shape of the rubber product should be considered, as it can affect its fit and function in the specific application.

(8)Compliance requirements: The rubber product may need to comply with certain regulatory or industry standards, such as FDA regulations for food-grade rubber products or industry-specific certifications for safety.

(9)Performance requirements: The specific performance requirements for the rubber product should be considered, such as the level of flexibility, strength, or resistance to wear and tear needed for the application.

English

English.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)